- Protap Sarker

- Mar 21, 2024

- 2 min read

As I stepped into the heart of industrial prowess, Bangladesh Steel Re-Rolling Mills Limited, I found myself immersed in a world where metal metamorphosis takes place, where raw steel ingots undergo a transformative journey into gleaming, sturdy products. The rolling process, a symphony of heat, pressure, and precision, unfolded before my eyes, revealing the intricate dance of machinery and human expertise.

The Beginning: From Ingot to Billet

The journey commences with the arrival of raw steel ingots at the mill. These ingots, typically crafted from recycled scrap metal or raw iron, bear the potential for transformation. In the cavernous confines of the factory floor, massive cranes hoist these heavy ingots onto the furnace, where they undergo a baptism of fire.

Heating the Forge: Furnace and Preheating

Within the fiery belly of the furnace, temperatures soar to staggering heights, turning the solid steel ingots into malleable, red-hot masses. Preheating is crucial to ensure uniformity and pliability, allowing the metal to yield to the shaping forces awaiting it in the rolling process. Skilled technicians monitor the furnace closely, adjusting temperatures and settings with precision born of years of experience.

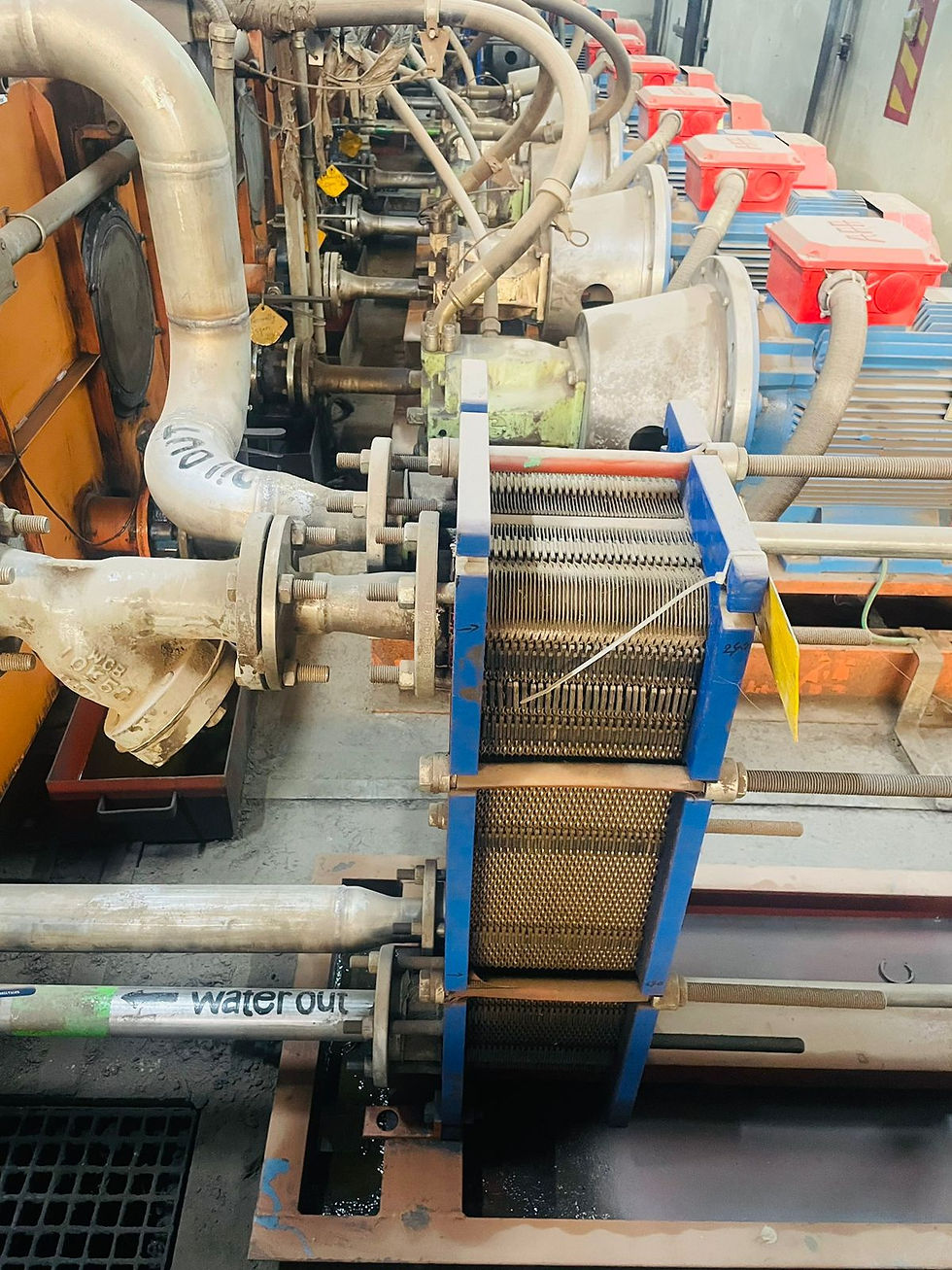

Into the Maw: Rolling Mill Stands

Once sufficiently heated, the ingots are guided to the rolling mill stands, colossal machines standing sentinel-like, ready to exert immense pressure and coax the metal into its desired form. Each stand in the rolling mill plays a specific role, gradually reducing the thickness and reshaping the steel ingot into elongated sections known as billets.

The Dance of Precision: Rolling Process

As the ingots pass through the rolling mill stands, they are subjected to immense pressure, exerted by a series of rotating rolls. These rolls, meticulously calibrated and maintained, impart the desired shape and dimensions to the metal, gradually transforming it from a bulky mass into sleek, elongated billets. The process demands precision and finesse, with technicians monitoring every aspect to ensure consistency and quality.

Cooling and Cutting: Finishing Touches

Emerging from the rolling mill stands, the hot billets embark on the final leg of their journey. Guided by conveyor belts, they are swiftly transported to the cooling area, where sprays of water quench their fiery surfaces, tempering them and enhancing their strength. Once sufficiently cooled, the billets are swiftly cut to the desired lengths, ready to be bundled and prepared for further processing or shipment.

Conclusion: The Artistry of Steel Rolling

Standing amidst the rhythmic clatter of machinery and the searing heat of the furnaces, I marveled at the artistry of steel rolling. It's a process that seamlessly melds human ingenuity with technological prowess, transforming raw materials into the building blocks of modern infrastructure. Bangladesh Steel Re-Rolling Mills Limited stands as a testament to the dedication and expertise of its workforce, shaping not just steel, but the very foundations of progress and development.